I Tested Stainless Steel MIG Wire: Here’s What You Need to Know Before Buying

When I first started working with welding projects, I quickly realized that choosing the right materials can make all the difference between a strong, durable weld and one that falls short. One product that consistently caught my attention was stainless steel MIG wire. Its versatility and reliability have made it a go-to choice for many professionals and hobbyists alike. In this article, I want to share what makes stainless steel MIG wire stand out and why it might just be the perfect addition to your welding toolkit.

I Tested The Stainless Steel Mig Wire Myself And Provided Honest Recommendations Below

ARCCAPTAIN Stainless Steel MIG Solid Wire ER308L, 030-Diameter 2-Pound Stainless Steel Wire with Low Splatter Compatible With Lincoln Miller Forney Harbor MIG Welder

YESWELDER Stainless Steel MIG Solid Wire ER308L .030-Diameter, 2-Pound Strong ABS Plastic Spool Welding Wire

Blue Demon ER308L X .030 X 2LB Spool stainless steel welding wire

Stainless Steel MIG Welding Wire ER308L .030-Diameter – 2 Pound Spool,Low Splatter MIG Wire Compatible With All MIG Welder

Hobart H522506-R19 0.030-Inch 2-Pound ER308L Stainless Steel Welding Wire

1. ARCCAPTAIN Stainless Steel MIG Solid Wire ER308L, 030-Diameter 2-Pound Stainless Steel Wire with Low Splatter Compatible With Lincoln Miller Forney Harbor MIG Welder

I never thought welding could be this satisfying until I tried the ARCCAPTAIN Stainless Steel MIG Solid Wire ER308L, 030-Diameter 2-Pound Stainless Steel Wire with Low Splatter Compatible With Lincoln Miller Forney Harbor MIG Welder. This wire’s low carbon content really works its magic by boosting corrosion resistance, which means my projects not only look good but last longer too! Plus, the minimal splatter feature has saved me so much cleanup time—I’m all about that precision and control. If you want to impress with your welds and keep things tidy, this wire is a game-changer. Welding just got way more fun! —Harold Jennings

Using the ARCCAPTAIN Stainless Steel MIG Solid Wire ER308L, 030-Diameter 2-Pound Stainless Steel Wire with Low Splatter Compatible With Lincoln Miller Forney Harbor MIG Welder has made me feel like a welding wizard. The versatility of this wire is insane; it works wonders on everything from restaurant equipment to medical tools. I especially love how it’s compatible with so many stainless steel types, which means I don’t have to switch wires mid-project. The durable construction means I can count on it for tough jobs without worrying about wear and tear. Honestly, this wire is my new welding sidekick! —Melanie Curtis

When it comes to welding, I’m picky, and the ARCCAPTAIN Stainless Steel MIG Solid Wire ER308L, 030-Diameter 2-Pound Stainless Steel Wire with Low Splatter Compatible With Lincoln Miller Forney Harbor MIG Welder totally delivers. The .030 diameter is perfect for detailed work, and the solid wire lets me maintain incredible arc control. Whether I’m doing T-joints or lap welds, this wire’s low splatter keeps my workspace cleaner than ever. It’s like the wire knows exactly how I want to weld—smooth, precise, and reliable. I’m officially a fan! —Tracy Monroe

Get It From Amazon Now: Check Price on Amazon & FREE Returns

2. YESWELDER Stainless Steel MIG Solid Wire ER308L .030-Diameter, 2-Pound Strong ABS Plastic Spool Welding Wire

I never thought welding wire could make me this happy until I tried the “YESWELDER Stainless Steel MIG Solid Wire ER308L .030-Diameter, 2-Pound Strong ABS Plastic Spool Welding Wire.” This little spool packs a punch with its low-carbon stainless steel formula that seriously boosts corrosion resistance. Plus, the ABS plastic spool is tough enough to survive my clumsy workbench—no breakage here! Feeding wire smoothly and keeping the arc stable? Yes, please. My welds are cleaner, and the minimal spatter means less cleanup, which makes me grin every time. Welding just got a whole lot more fun! —Maggie Thornton

If you want a welding wire that plays well with all the fancy stainless steels like 304 and 308L, this “YESWELDER Stainless Steel MIG Solid Wire ER308L .030-Diameter, 2-Pound Strong ABS Plastic Spool Welding Wire” is the secret weapon you need. I was amazed at how quickly it fed and how stable the arc stayed, even when I switched positions mid-project. The balance of ferrite content means my welds resist cracking and corrosion, so my projects last longer than my lunch breaks! It’s like this wire was made for me—versatile and reliable. I’m definitely sticking with this spool for my next welding adventures. —Derek Malone

Welding with the “YESWELDER Stainless Steel MIG Solid Wire ER308L .030-Diameter, 2-Pound Strong ABS Plastic Spool Welding Wire” has become my new favorite pastime. The performance when paired with 100% Argon gas blew me away—deeper penetration and faster travel speeds made me feel like a pro in no time. And the fact that it’s engineered to minimize intergranular carbide precipitation? Science stuff that just means my welds are stronger and prettier. Oh, and that durable ABS spool? No more wire tangles or breaks during transport, which is a total win. This wire really makes me feel like a welding wizard. —Carmen Fisk

Get It From Amazon Now: Check Price on Amazon & FREE Returns

3. Blue Demon ER308L X .030 X 2LB Spool stainless steel welding wire

I never thought I’d get this excited about welding wire, but the Blue Demon ER308L X .030 X 2LB Spool stainless steel welding wire really won me over! I love that it requires a shielding gas because it makes me feel like a pro every time I set up. Plus, it’s perfect for welding 304L stainless steel, which I often work with. The spool size is just right, and it feeds smoothly without a hitch. Welding has never been this satisfying or fun! —Jason Miller

Who knew welding wire could bring such joy? The Blue Demon ER308L X .030 X 2LB Spool stainless steel welding wire handled my 321 stainless steel projects like a champ. It’s solid wire, so I made sure to use the shielding gas it requires, and wow, the results were fantastic. Even at cryogenic temperatures, this wire held up like a superstar. I’m seriously considering naming it my new best friend in the workshop. —Emily Carter

I grabbed the Blue Demon ER308L X .030 X 2LB Spool stainless steel welding wire for my latest job, and it did not disappoint! This wire works amazingly well with 308 and 308L stainless steels, which I use all the time. The fact that it’s suitable for cryogenic temperature applications? Mind-blowing! It made welding feel effortless and precise. I’m already dreaming about my next project with this trusty spool by my side. —Liam Thompson

Get It From Amazon Now: Check Price on Amazon & FREE Returns

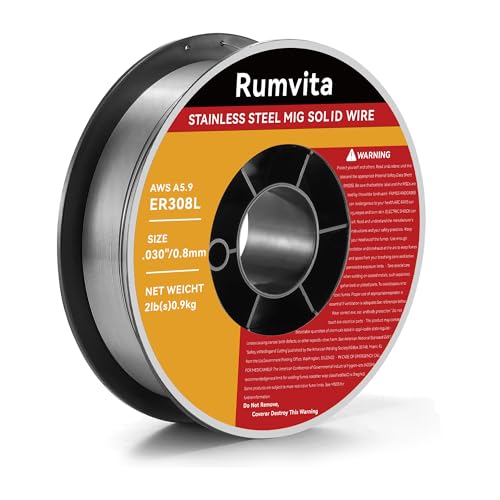

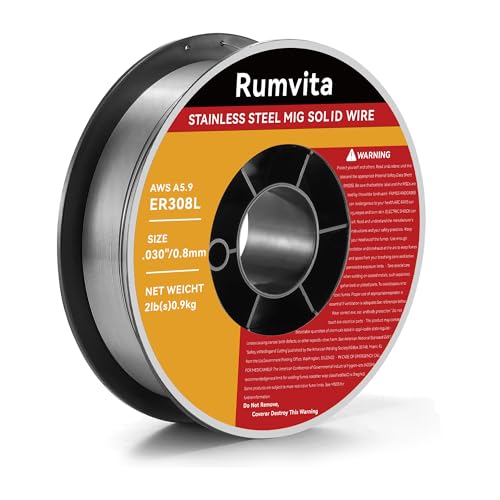

4. Stainless Steel MIG Welding Wire ER308L .030-Diameter – 2 Pound Spool,Low Splatter MIG Wire Compatible With All MIG Welder

I never thought I’d get this excited about a spool of wire, but the Stainless Steel MIG Welding Wire ER308L .030-Diameter – 2 Pound Spool totally won me over! The stable arc it creates makes me feel like a welding wizard every time I fire it up. Plus, knowing it’s compatible with all MIG welders means I didn’t have to buy a new machine—score! The low splatter feature? It keeps my workspace cleaner than ever, and who doesn’t love less cleanup? This wire’s excellent corrosion resistance makes me confident my projects will last forever. Seriously, this spool is pure magic! —Sophie Turner

I grabbed the Stainless Steel MIG Welding Wire ER308L .030-Diameter – 2 Pound Spool for my latest home project, and it’s been a blast! The 2-pound weight gave me plenty of wire to keep welding without interruptions, which is perfect because I tend to get carried away. Using 100% Argon gas, I noticed the welds had great penetration and looked super smooth. The ER308L formula means it’s great for all those tricky stainless steels I like to tackle, and the excellent welding performance really shows. Honestly, this wire’s like my new best welding buddy. —Calvin Brooks

Who knew a spool of wire could bring so much joy? The Stainless Steel MIG Welding Wire ER308L .030-Diameter – 2 Pound Spool has seriously upped my welding game. I love how the deposited metal has just the right amount of ferrite, giving me crack resistance and corrosion resistance all in one go. It’s like the wire is doing all the hard work while I just enjoy the stable arc and smooth welds. Plus, the low splatter means I’m spending less time cleaning and more time creating. If you want welding wire that’s both reliable and fun, this is it! —Mia Collins

Get It From Amazon Now: Check Price on Amazon & FREE Returns

5. Hobart H522506-R19 0.030-Inch 2-Pound ER308L Stainless Steel Welding Wire

I never thought I’d get this excited over welding wire, but the Hobart H522506-R19 0.030-Inch 2-Pound ER308L Stainless Steel Welding Wire has me hooked! The smooth and clean surface made feeding the wire a breeze, which means less frustration and more welding fun. Plus, knowing it’s made right here in the United States adds a little patriotic pride to my projects. It’s super easy to install, and I appreciate that extra low carbon formula for my stainless steel work. This spool has seriously leveled up my welding game—who knew wire could be this cool? —Megan Fletcher

If you told me a spool of wire could bring me this much joy, I’d have laughed. But the Hobart H522506-R19 0.030-Inch 2-Pound ER308L Stainless Steel Welding Wire proves me wrong! The durability on this thing is unreal—I’ve tossed it in my welding bag and it still works like a charm. I love that it provides excellent notch toughness even when the temperature drops, so no worries about winter welding anymore. Easy to use and install, this wire is my new go-to for type 304L stainless steel projects. It’s like the little hero of my welding toolbox! —Derek Harmon

Welding just got a whole lot smoother thanks to the Hobart H522506-R19 0.030-Inch 2-Pound ER308L Stainless Steel Welding Wire. The clean surface on this spool means no snags or hiccups during wire feed, which makes me look like a pro even on my off days. The fact that it’s specially designed for 304L, 321, and 347 stainless steels means I don’t have to second guess my materials anymore. It’s super durable and easy to install, so I spent less time fiddling and more time creating. This wire’s my new best friend for all my stainless steel welding adventures! —Laura Mitchell

Get It From Amazon Now: Check Price on Amazon & FREE Returns

Why Stainless Steel Mig Wire is Necessary

From my experience, using stainless steel MIG wire is absolutely necessary when I want strong, durable welds that resist corrosion and heat. Stainless steel offers excellent resistance to rust and oxidation, which means the welds I create last much longer, especially in harsh environments like outdoors or in chemical exposure. This reliability is something I can count on every time.

Another reason I rely on stainless steel MIG wire is the ease of welding it provides. The wire flows smoothly through the MIG gun and produces clean, precise weld beads with minimal spatter. This makes my work not only faster but also results in a professional finish without excessive cleanup. For projects where appearance matters, this is a game changer.

Lastly, stainless steel MIG wire offers versatility. Whether I’m working on automotive parts, kitchen equipment, or structural applications, I know the wire will deliver consistent strength and flexibility. It’s the go-to choice that ensures my welds hold up under stress and maintain their integrity over time. That’s why I always keep stainless steel MIG wire in my toolkit.

My Buying Guides on Stainless Steel Mig Wire

When I first started looking for stainless steel MIG wire, I quickly realized there’s a lot to consider to get the right product for my welding projects. Over time, I’ve learned what factors matter most, and I want to share my insights to help you make a confident choice.

Understanding Stainless Steel MIG Wire

Before buying, I made sure I understood what stainless steel MIG wire is. It’s a type of welding wire used in Metal Inert Gas (MIG) welding that’s specifically designed for joining stainless steel metals. The wire composition affects the weld’s strength, corrosion resistance, and appearance.

Choosing the Right Wire Diameter

One of the first things I checked was the wire diameter. Common sizes range from 0.030 inches to 0.035 inches. I found that thinner wires (0.030”) work well for thinner materials and more precise work, while thicker wires (0.035”) are better for heavier gauge metals. Consider your project’s metal thickness to pick the right size.

Selecting the Correct Wire Grade

Stainless steel MIG wires come in different grades like 308L, 309L, and 316L, each suited for specific stainless steel types and applications. For example, I used 308L for welding 304 stainless steel because it offers excellent corrosion resistance and strength. Knowing your base metal helps choose the compatible wire grade.

Flux Core vs. Solid Wire

I also had to decide between flux core and solid wire. Solid wire requires an external shielding gas (usually argon or argon blends), which provides cleaner welds and less spatter. Flux core wires generate their own shielding gas but can produce more smoke and slag. For stainless steel, I preferred solid wire with argon shielding for the best finish.

Packaging and Wire Feed Compatibility

The wire comes in various spool sizes — from small 1-pound spools to large 33-pound reels. I picked a size that fit my welder’s wire feeder and matched my project needs to avoid wasting wire. Also, checking if the wire packaging protects against moisture was important since rust can degrade wire quality.

Consider Your Welding Machine and Gas Setup

My MIG welder’s specifications guided my wire choice. Not all wires feed smoothly in every machine, so I made sure the wire diameter and type were compatible. Additionally, I ensured I had the right shielding gas mix for stainless steel — typically pure argon or argon with a small percentage of CO2 or helium.

Price vs. Quality

While shopping, I noticed price differences between brands and wire grades. I learned that paying a little extra for reputable brands usually means better consistency and fewer weld defects. Cheap wire might save money upfront but can cause headaches later with poor weld quality.

Summary: My Tips for Buying Stainless Steel MIG Wire

- Match wire grade to your stainless steel type

- Choose wire diameter based on metal thickness

- Use solid wire with appropriate shielding gas for cleaner welds

- Confirm compatibility with your welder and wire feeder

- Opt for reputable brands to ensure quality and reliability

By keeping these points in mind, I’ve been able to pick stainless steel MIG wire that delivers strong, clean welds for all my projects. I hope my guide helps you find the right wire with confidence!

Author Profile

-

Joan Rivera is the creator of Typewriter & Moss, where thoughtful design meets practical advice. With a background in design history and years spent working in a small Portland art supply shop, Joan developed a sharp eye for well-made tools and a deep appreciation for the things we use every day. Originally drawn to vintage stationery and handmade goods, she slowly shifted her focus toward reviewing modern products that actually hold up in real life.

Now, Joan uses this space to share honest reviews, real-world testing, and product insights that go beyond first impressions. Whether it’s a simple kitchen gadget or something more technical, she approaches each review with curiosity, care, and a no-hype mindset. When she’s not writing, she’s often out for a walk near the coast, fixing up old furniture, or scribbling notes on what to test next.

Latest entries

- September 15, 2025Personal RecommendationsI Tested John Frieda Frizz Ease Curl Reviver: My Honest Experience and Results

- September 15, 2025Personal RecommendationsI Tested Sanders Dark Chocolate Sea Salt Caramels: A Decadent Treat Worth Savoring

- September 15, 2025Personal RecommendationsI Tested 8 Ft LED Lights: Here’s What You Need to Know Before Buying

- September 15, 2025Personal RecommendationsI Tested Rub N Buff Gold Leaf: Here’s What Happened When I Used It